The features about popcorn bag

High-quality service

Hibags strives to provide our customers with high-quality and most satisfactory stand-up bulk popcorn bags wholesale services. We provide customized popcorn bags bulkwholesale services in size, colour and shape.

Improve brand influence

This means that we can help you design your popcorn bag according to actual needs. We also provide product logo printing services, popcorn bags bulk and wholesale services. Printed popcorn bags can help you increase your brand influence.

Environmentally friendly materials

The use and production of packaging materials is a crucial part of ensuring food safety. We use high-safety plastic and film packaging materials to provide customers with environmentally friendly popcorn bags bulk.

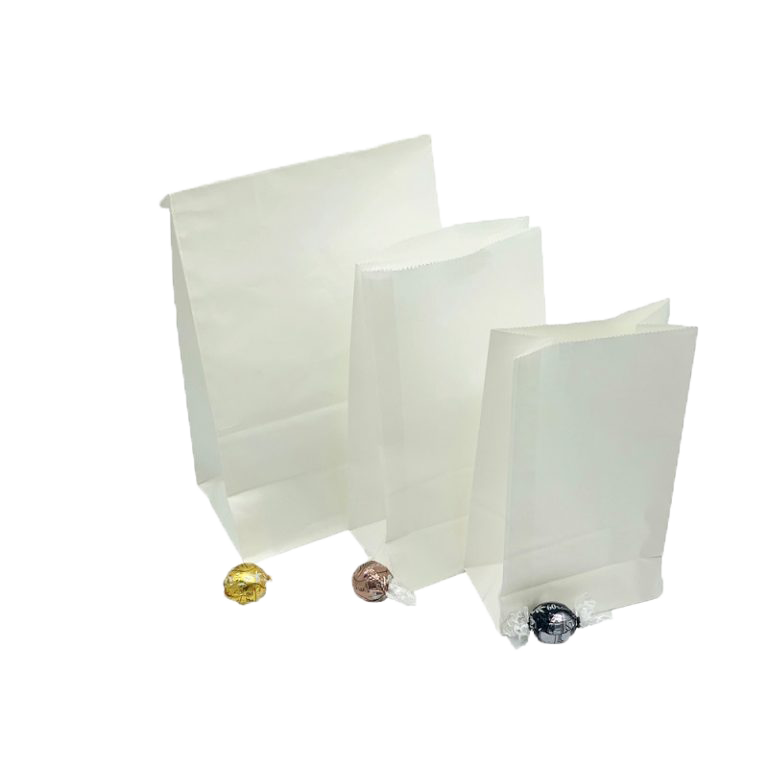

White Kraft Paper Popcorn Bag

Hibags provides popcorn bags bulk and wholesale service. The kraft paper popcorn bags bulk has a strong waterproof function, the white is pure and simple, and the bag is beautiful. It has a wide range of uses in the packaging industry and can store and package popcorn, coffee and other items. The kraft paper popcorn bags bulk is very resistant to water, drop, mildew and moisture. More importantly, it is also lined with a heat-sealable polymer material that prevents air leakage. Moreover, both ends of the bag are equipped with tearable and reclosable zippers..

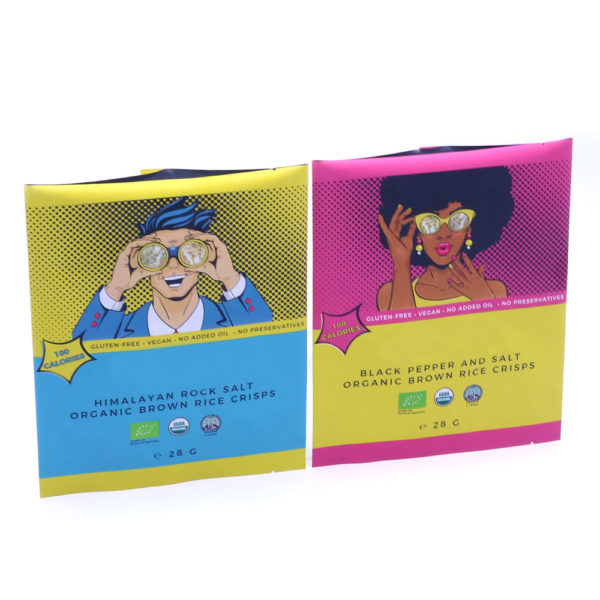

Paper popcorn bag with window

Hibags provides popcorn bags bulk and wholesale service. The white popcorn bags bulk with a window is made of paper materials. This material selection can provide a dry storage environment for the popcorn, and the rigid packaging will ensure the safety of the internal products during the delivery process. Besides, popcorn bags bulk can be customized in various sizes and colours that you like. Its transparent window design can provide customers with clear product interior ideas. The top of popcorn bags bulk with a window also provides customers with a unique sealing design.

Foldable paper popcorn bag

Hibags provides popcorn bags bulk wholesale service. This paper popcorn bags bulk can be easily folded and flexibly deformed. It not only occupies a small area, lightweight but also easy to carry out. It also has a sealing device on top. Usually, they are made of MOPP, VMPET and PE. It is an ideal choice for popcorn packaging. The resealable paper bulk popcorn bags with a valve can keep the inner product dry for the storage of popcorn. Its non-toxic materials provide them with a safe storage environment and can also be used to store food such as coffee, cigarettes or candy.

Professional nut bag manufacturer

Hibags have over 16 years of experience in the flexible packaging industry. We promote our clients’ brands with excellent snack nut bags and films! Furthermore, we’re continuously improving product quality, self-skills and management levels, etc. Our commitments are Reasonable Prices and SatisfactoryLeading Time, Professional After-Sales Service, and Mutual Benefits &Developments.

Tin popcorn bag with valve

Hibags provides popcorn bags bulk and wholesale service. These popcorn bags bulk is more similar to a kraft paper tin-tie popcorn bags bulk , but it has more materials, such as paper or food-grade plastic. This food-grade plastic can provide a safe and transparent packaging environment. Due to its high water resistance and deformation resistance, it can ensure that the popcorn remains dry and intact throughout the delivery process.These bulk popcorn bags has an iron tie seal and a valve design.

Aluminium foil popcorn bag with zipper

Hibags provides popcorn bags bulk and wholesale service. These popcorn bags bulk comes with a zipper. The aluminium foil popcorn bag bulk is characterized by no additions. The bag is a transparent and pure packaging composite film, which contains neither aluminium nor pigments and pigments. It is made directly from polyethene raw materials. The most significant advantage of the aluminium foil bag is that it can block oxygen and moisture. The water and oxygen permeability is 1, which can keep the freshness of popcorn well. In addition, aluminum foil bags have good heat resistance, good light reflectivity and gloss, so popcorn can maintain a good shape in both high and low temperature conditions.

About popcorn bags bulk

Protect the food itself

It can be said that the purpose of all types of food packaging bags is essentially the same, that is, to protect the food itself. Therefore, the first role of popcorn packaging bags is to protect the popcorn directly produced from the factory. During the whole process of popcorn from being produced to being purchased by consumers, it will be affected by various or external factors or some of its facets. Therefore, what the popcorn packaging bag should do is to protect the quality of the popcorn produced and prevent volatilization, penetration, and collision and squeezing of foreign objects on it. With popcorn packaging, it can reduce the loss during storage, transportation, and sale, save costs, and benefit manufacturers.

Beautify goods

The pursuit of beauty is human nature, and good popcorn packaging can make your product stand out from the crowd. Exquisite packaging can undoubtedly attract people’s attention and make people pleasing to the eye, so now, more and more food manufacturers are putting more marketing energy on the packaging. Think about it, when you watch a movie with your family and friends in the theatre, holding a bag of delicious popcorn printed with pleasing patterns, does the movie-watching atmosphere instantly increase a lot?

Enhance product value

Creative popcorn packaging tends to make your products more valuable and more attractive to customers. Positioning the effect on your popcorn’s outer packaging will unintentionally increase the value of your product, make people want to buy, and bring you more benefits.

Advertising marketing and brand building.

Nowadays, the image and culture of a company is a kind of potential value for the company. Colour-printing delicate patterns on your popcorn packaging bags will significantly increase the sales of your company’s products. The colour printing design of the packaging bag is an important part of product marketing, which can directly show the highlights of your product. A good popcorn packaging bag design will be deeply reflected in the hearts of consumers and become a potential endorsement of your brand. The world-renowned food manufacturers, without exception, have invested a lot of human and financial resources in the design of the outer packaging of their products.

Our company mainly has popcorn packaging bags made of plastic, paper and aluminium foil.

Plastic packaging refers to plastic packaging. Plastics are mainly made of synthetic or natural polymer resins. Adding various additives has flexibility under specific temperature and pressure and can fix its shape after cooling. Plastic is now the most widely used packaging material. Plastics commonly used in packaging mainly include polyethene (PE), polypropylene (PP), polyester (PET), nylon (PA), polystyrene (PS), polyvinyl chloride (PVC), polyvinylidene chloride ( PVDC) and more than a dozen kinds. The company mainly uses film bags made of polyester materials.

According to their properties, plastics can be divided into two categories: thermoplastics that can be melt-moulded repeatedly and can basically maintain their characteristics and thermosets that can only be melt-moulded once.

Thermoplastics

It is mainly made of polyaddition resin as base material and adding an appropriate amount of additives. It can be repeatedly heated to soften and flow in a specific temperature range and cool to harden, and its resin chemical composition and basic properties will not change. This type of plastic has simple moulding and processing, good packaging performance, and can be repeatedly moulded. But it has low rigidity and low heat resistance. Commonly used plastic varieties on popcorn packaging include polyethene, polypropylene, polyvinyl chloride, polyvinyl alcohol, polyamide, polycarbonate, polyvinylidene chloride, etc.

Thermosetting plastics

It is mainly made of polycondensation resin as base material, adding fillers, curing agents and other appropriate additives; which is cured at a specific temperature for a certain period and then heated again. It can only be decomposed and cannot be softened, so it cannot be repeatedly moulded into shapes. This type of plastic has the characteristics of good heat resistance, rigidity, and non-melting, but it is brittle and cannot be moulded repeatedly. Amino plastics, phenolic plastics, epoxy plastics, etc., are commonly used on popcorn packaging.

Advantages of plastic packaging bags:

- The density is small, the specific strength is high, and a higher packaging yield can be obtained, that is, the “package volume or packaging area per unit mass.”

- Most plastics have good chemical resistance, good acid resistance, alkali resistance, resistance to various organic solvents, and long-term storage without oxidation.

- The moulding is easy, and the required moulding energy consumption is lower than that of metal materials such as steel.

- It has good transparency and easy colouring.

- It has good strength, high strength per unit weight, impact resistance, and easy modification.

- The processing cost is low.

- Excellent insulation.

Our company mainly deals in the following four types of paper packaging bags:

- Kraft paper: It is made of softwood sulphate natural colour pulp, which is strong, usually yellowish-brown, in addition to light brown, cream or white. The thickness is between 80 grams and 120 grams. Kraft paper has high tensile strength, such as single gloss, double gloss, stripes, and no grains. Mainly used to make environmentally friendly paper bags for supermarkets, paper bags for food delivery, paper bags for dried fruits such as chestnuts, envelope bags, archive bags, medical record bags, etc.

- White cardboard: single-layer or multi-layer combination made of bleached chemical pulping and fully sizing. White cardboard has a smooth surface and firm texture. At present, imported white cardboard has a larger market share in the domestic market. White cardboard is mainly used to make high-end and exquisite handbags, packaging bags, gift boxes, business cards, etc.

- Coated paper: The primary raw materials are coated base paper and paint. Paints, adhesives and auxiliary materials are made into coatings, which are coated on the surface of cardboard by special equipment, dried and calendered. The surface is smooth and has good printing performance, and the thickness is 70-250 grams. It is mostly used in cigarette cases, labels, cartons, etc.

- Offset paper: The paper’s surface is white and smooth, but the whiteness, tightness and smoothness are lower than that of coated paper. It is suitable for printing monochromatic or multi-colour book covers, texts, inserts, pictorials, maps, posters, and colour trademarks. And various packaging products, in recent years, it has also been used to make dry fruit packaging bags such as chestnuts that are not demanding.

Advantages of paper packaging materials:

- Wide sources of raw materials, low cost, diverse varieties, easy to form mass production;

- Good processing performance, easy composite processing and excellent printing performance;

- Have certain mechanical parts, lightweight, good cushioning parts;

- Good hygiene and safety;

- The waste can be recycled, and there is no white pollution.

Aluminium foil bags are made into aluminium foil bags by dry compounding aluminium and other high barrier materials according to aluminium’s unique properties. It is an ultra-thin plate formed by rolling high-purity aluminium several times and is an excellent heat conductor and light-shielding body. The purity of aluminium foil for packaging is above 99.5%. The vacuum aluminized film is a kind of film that deposits aluminium vapour onto various base films in a high vacuum state. The thickness of the aluminized layer is generally 350-400A.

Aluminium has lightweight and lustre characteristics, strong reversal ability, good barrier properties, impermeable body and water vapour, strong temperature adaptability, stable shape at high or low temperature, strong shading and excellent fragrance retention. Therefore, the aluminium foil bag has good moisture-proof, barrier, light-proof, anti-permeability and beautiful functions. The water vapour transmission rate can reach <0.015 g/(m2·24h)>. It also has the function of heat sealing and can be vacuum-packed. The appearance of the composite aluminium foil bag is opaque, silver-white, with anti-gloss, and can be stored in an environment where the temperature is ≤38℃ and the humidity is ≤90%.

Advantages of aluminium foil packaging bags:

(1) Strong air barrier performance, anti-oxidation, waterproof and moisture-proof.

(2) Strong mechanical properties, high blast resistance, strong puncture and tear resistance.

(3) High-temperature resistance (121°C), low-temperature resistance (-50°C), oil resistance and good fragrance retention performance.

(4) Non-toxic and tasteless, in line with food and drug packaging hygiene standards.

(5) Good heat sealing performance, flexibility, and high barrier performance.

It can protect food from rotting, healthy, safe, hygienic and easy to carry.

Moreover, both ends of the bag are equipped with tearable and reclosable zippers. These designs also simplify the use process, and its thicker bottom design makes bulk popcorn bags more prominent and better. Now, our customized bulk popcorn bags wholesale service also provides good discounts for customers who have ordered a certain number of popcorn bags.

Personalized packaging

With the continuous improvement of the technological level, similar products are becoming more and more homogeneous. The competition between enterprises has transformed into the competition of image power in a certain sense. The popcorn packaging design is a simple visual stimulus, but more importantly, it creates an information exchange design with the designed product. Popcorn packaging cleverly applies the law of colour and emotion and gives full play to the suggestive role of colour. This way can arouse the attention and interest of a wide range of consumers. Psychological research shows that different colours have different psychological responses to consumers. Warm colours give people a feeling of enthusiasm, glory, and excitement; cool colours give people a refreshing and elegant feeling. Of course, the colour associations are not limited to the pure colours on the colour spectrum. Other colours are also the same. For example, pink is synonymous with shyness and romance. She is a symbol of supple, feminine, sexy and intimacy; The white is spotless. The feeling of black, especially blue, symbolizes the “emotional colour” of nobility, excellence, and elegance. This feeling of colour is inherent in people and is one of the driving forces of colour psychology.

In addition, the colour of the packaging design should pay more attention to factors such as eye-catching and contrast to reflect the attractiveness and charisma of the colour. Consumers can adequately associate the product’s characteristics and performance and enhance consumers’ trust and love for the product. Feelings. Therefore, in order to make the design of popcorn packaging have specific characteristics and show a distinctive personality. It is necessary to work hard on selecting and combining colours to make it unconventional, with distinct personality characteristics, novel and unique colour styles, and Typical image. Popcorn packaging is a combination of protection function and artistic beauty and an innovative combination of practicality and novelty. A good popcorn packaging bag design has a strong visual appeal and can quickly, vividly and accurately convey the information of the product. It is the resonance of the mentality of the producer, the mentality of the creator and the mentality of the buyer’s needs. The design of popcorn packaging can only promote the consumption of popcorn products by successfully grasping and accurately using consumers’ psychology, catering to consumers’ preferences, satisfying consumers’ needs, and stimulating and guiding consumers’ emotions. Only by effectively embodying the aesthetic function and market value of popcorn packaging design can it stand out in the fierce business battle and secure the winning ticket.

Quality first

People have high requirements for food packaging. Since foods such as popcorn often require long-distance transportation to be delivered from the place of production to the supermarket shelves, ensuring the food’s quality and hygiene is particularly important. It may take longer for the popcorn to go from the shelf to the shopping cart and be consumed by consumers. Cutting-edge technology can help popcorn packaging to ensure that the food is fresh and hygienic. The combination of composite materials with different characteristics provides an ideal packaging for popcorn. For example, the bottom material of a popcorn bag is quite different from the lid.

Safety first

Hazardous substances are not limited to the food itself-they can also come from packaging materials. In 2010, researchers from the Zurich Food Safety Agency, Switzerland, discovered that mineral oil residues in cardboard popcorn packaging would migrate to the popcorn. The root of this problem is that the ink used in newspaper printing enters the packaging through recycled paper. Occasionally, trace residues can also come from the ink used in popcorn packaging printing. These mineral oil residues can evaporate at room temperature and then migrate to the popcorn in the package. Even when the popcorn shipping package contains recycled paper, there is a possibility of mineral oil migration. According to the World Health Organization Joint Committee of Experts on Food Additives and FAO, certain mineral oils may cause cancer.

Multifunctional, thin and light

In terms of unique materials for popcorn packaging, the food industry will continue to increase the demand for functional packaging such as high barrier, cooking resistance, UV resistance, light-proof, antibacterial, breathable, and anaerobic in the future. At the same time, there will be a trend toward thinner and lighter packaging.

Biological packaging and degradable packaging

In addition to popcorn packaging safety, more and more consumers hope that popcorn packaging can be recycled. The Swedish carton manufacturer Tetra Pak conducted a survey of 6,000 consumers in 10 countries and found that recycled packaging is one of the public’s first choices because it is considered more environmentally friendly. Consumers and legislators are paying more and more attention to food packaging issues, which encourages the efficient use of resources. This trend is particularly evident in Europe. Take the Netherlands as an example. The country levies taxes on packaging manufacturers based on the average carbon dioxide emissions of packaging materials-0.36-0.57 euros per kilogram of aluminium and 0.06 euros per kilogram of cardboard. Popcorn packaging materials are primarily disposable products. In order to reduce the environmental impact of packaging waste, waste reduction treatment has become one of the development directions. In the process of reduction, biodegradable materials play the leading role. For example, popcorn packaging can be produced using biodegradable plastics, and these plastics use a certain percentage of renewable raw materials. After eating, popcorn packaging can be processed and composted together with food residue. As people’s awareness of environmental protection has increased, recyclable paper food packaging has become more and more popular in China. According to statistics, paper packaging currently accounts for about 40% of China’s packaging materials, and this proportion may increase further.

Smart packaging

Some high-tech and new technologies are also being continuously introduced into the popcorn packaging industry. The development of the Internet has integrated sensors, chips and printed electronic labels with the traditional popcorn packaging industry. In the future, “smart” or “active” packaging will reduce food waste. Experts worldwide are working hard to find new ways to provide consumers with information on food’s perishability and prevent food from spoiling. These new systems will provide information on the product’s current state while using deoxidizers or particular acids to extend the shelf life. For example, a US company is developing a packaging with integrated microchips to collect product status information, such as humidity and temperature, and issue an alarm when it exceeds or falls below a preset temperature. Of course, for business, the introduction of intelligent technology must first consider the cost issue. For low-cost foods like popcorn, the introduction of innovative packaging attempts to increase the added value and availability of the product.

The top of bulk popcorn bags with a window also provides customers with a unique sealing design. If the user has not consumed the product at one time, the product can be sealed and stored in the bag to continue eating next time. Hibags has bulk popcorn bags wholesale service. If you buy a large number of bulk popcorn bags, you will get a significant discount.

Its non-toxic materials provide them with a safe storage environment and can also be used to store food such as coffee, cigarettes or candy. Now we provide customers with bulk popcorn bags customization service, customize your favourite size, colour and shape to make your bulk popcorn bags more personalized.

Hibags promises that all printed bulk popcorn bags are made of non-toxic materials and are printed with advanced printing technology. Our bulk popcorn bags wholesale service will provide satisfactory discounts and ensure punctual delivery and high quality products. The service will offer substantial discounts to customers who have placed large orders.

The iron tie with a valve ensures the convenience of use of bulk popcorn bags and provides a ventilated environment, thereby improving the popcorn storage environment. The iron tie bulk popcorn bags with valve is ideal for popcorn packaging. It is generally made of laminated materials, PET, AL and PE. Hibags can customize its size and colour according to customer requirements, and it is printed with a logo or brand label. Our customized bulk popcorn bags wholesale service provides high-quality products at affordable prices.

You can design your bulk popcorn bags pattern or print the brand logo on the bulk popcorn bags. Our advanced printing technology will help you create a clear, colorful and long-lasting appearance. Now, our customized bulk popcorn bags wholesale service also provides good discounts for customers who have ordered a certain number of popcorn bags.